| Home | About Us | Product | Know How | Contact Us | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Copper Alloy Heat Exchanger Tubes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Supply material according to customer's designatal standard such as GB/T 8890, ASTM B111, BS 2781, EN 12451, DIN 1785, JIS and other special standard and so on. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

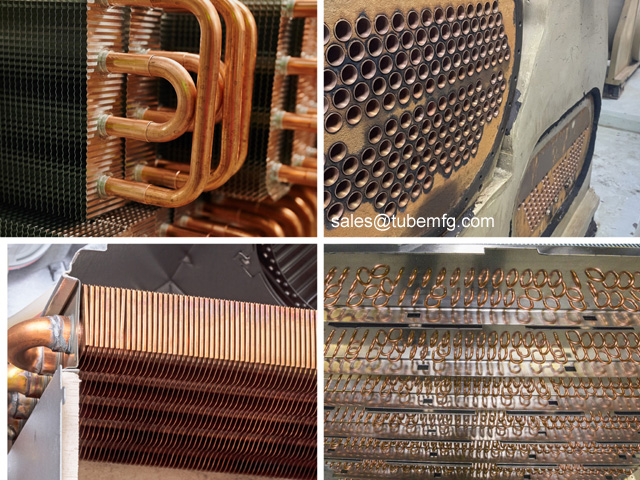

| Engine cooler, power plant condenser, marine heat exchanger, compressor cooler, petrochemical refinery cooler, motor cooler, seawater desalination evaporator, air conditioning cooling system and other fields. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Good Characteristics | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Thermal conductivity, good conductivity, wear resistance, plasticity, good cold bedning property, easy to welding and machining, the seawater corrosion resistance is strong. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

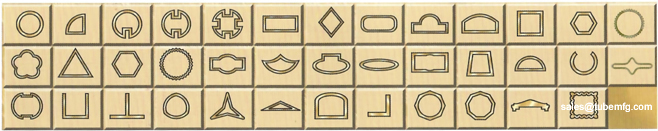

| We can produce copper and copper alloy products in more than 40 kinds of alloy including copper, brass, copper-nickel, bronze with thousands of sizes. Also we can develop copper and copper alloy tube, bars, profiles with special property and application according to customers' requirement. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Section shapes of shaped tubes & bars can be produced. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Copper tube, as a common metal material, is mainly composed of copper and may contain other alloying elements. It has a wide range of applications in various fields, especially in industries such as construction, refrigeration, heating, water systems, and shipbuilding. Firstly, in terms of material, copper tubes are mainly made of pure copper or copper alloys, which have excellent conductivity, thermal conductivity, and ductility. These characteristics enable copper tubes to perform excellently in electrical and thermal transmission systems. Secondly, copper tubes have a wide range of applications. In the field of construction, copper tubes are commonly used in cold and hot water pipeline systems because they have good corrosion resistance and can resist the erosion of various chemicals. Copper tubes are widely used in refrigeration and heating systems due to their efficient thermal conductivity, ensuring efficient operation of the system. In addition, copper tubes are also commonly used in water systems, such as tap water and drainage systems, as well as pipeline systems in shipbuilding. There are various types of copper tubes, including hard copper tubes, semi hard copper tubes, soft copper tubes, and stretched copper tubes. These different types of copper tubes undergo different processing and treatments during the manufacturing process to meet the needs of different applications. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The advantages of our copper tubes include: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| High quality: Our copper tubes are manufactured to meet industry standards and undergo rigorous quality control measures to ensure durability and reliability. Excellent corrosion resistance: The copper material used in our tubes has excellent resistance to corrosion, ensuring a longer lifespan for the tubing. Superior thermal conductivity: Copper is known for its high thermal conductivity, allowing for efficient heat transfer in heating and cooling systems. Versatility: Our copper tubes are versatile and can be used in a wide range of applications, including plumbing, HVAC systems, refrigeration, oil fields, instruments, household products, and so on. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Home | About Us | Product | Know How | Contact Us | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||